ENAMEL PAINT PROCESSING

We have been continuing our activities for many years by prioritizing customer satisfaction.

ENAMEL PAINT PROCESSING

Depending on the chosen application process the colours need to have different viscosities. For roller coating, for example, more liquid colours are required (i.e. with a higher organic part). Correspondingly each different application procedure will require a different drying time. After the application of the colour the printed pane has to be dried (at a temperature of approximately 170–190 ∘C

“>∘C∘C

). Then the pane is thermally toughened and at the same time the enamel coating is fused onto the surface of the glass.

ENAMEL PAINT PROCESSING

Depending on the chosen application process the colours need to have different viscosities. For roller coating, for example, more liquid colours are required (i.e. with a higher organic part). Correspondingly each different application procedure will require a different drying time. After the application of the colour the printed pane has to be dried (at a temperature of approximately 170–190 ∘C

“>∘C∘C

). Then the pane is thermally toughened and at the same time the enamel coating is fused onto the surface of the glass.

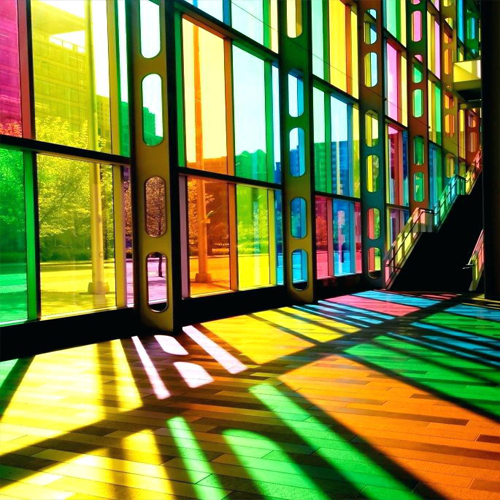

The enamelled glass is a type of glass produced by applying a ceramic paint onto its surface, and then it is subjected to drying and tempering process. The glass may be enameled by a roller coating machine or by a silk screen printing method.

Advanatges of the enamelled glass:

high resistance to an exposure to environmental conditions and thermal stresses,

higher resistance to mechanical damages,

properties of the safety glass – reduced risk of wounding when the glass pane is broken,

a rich colour palette (RAL)

The glass is enamelled by means of the roller coating machine:

The glass of Effect glass is enamelled by means of the roller coating machine thank to that a thickness of the paint layer can be differentiated on the respective shapes or the figures.

Production capabilities:

The production facility of Effect glass has at its disposal two types of the rollers:

(25 grooves/inch) for applying the thinner enamel coatings – the semi-transparent elements, so called satin glass effect, effect of acid-etching imitation,

(55 grooves/inch) for applying the thicker enamel coatings, making the non-transparent elements featuring different colour schemes.

Glass made with the silk screen printing method:

The silk screen printing is a technological process that consists in applying a paint on the different types of the surfaces by means of a sieve, on which is mapped the printed image.

In case of glass, enamel is applied by means of the sieve, which is prepared depending on the size, shape and pattern. After its application, the glass is subjected to drying, and then the tempering process. The glass with the silkscreen print is frequently found in the contemporary architecture. It features not only the decorative vales, but it is also safe and resistant to the variable atmospheric conditions.

+90 (535) 543 76 74

+90 (535) 543 76 74

FLOAT GLASS

FLOAT GLASS TINTED GLASS

TINTED GLASS REFLECTIVE GLASS

REFLECTIVE GLASS LOW-E / SOLAR LOW-E GLAS

LOW-E / SOLAR LOW-E GLAS TEMPERED GLASS

TEMPERED GLASS DECORATIVE GLASS

DECORATIVE GLASS LAMINATED GLASS

LAMINATED GLASS TRIPLE GLAZING SYSTEM

TRIPLE GLAZING SYSTEM DOUBLE GLAZING SYSTEM

DOUBLE GLAZING SYSTEM LAMINATION PROCESS

LAMINATION PROCESS AIRPORTS

AIRPORTS HOSPITALS

HOSPITALS UNIVERSITY & SCHOOL

UNIVERSITY & SCHOOL HOTELS

HOTELS SHOPPING MALL

SHOPPING MALL RESIDENTIAL BUILDING

RESIDENTIAL BUILDING RESIDENTAL & BUSINESS CENTER

RESIDENTAL & BUSINESS CENTER OTHERS

OTHERS +90 (262) 375 32 11

+90 (262) 375 32 11