GRINDING PROCCESS

We have been continuing our activities for many years by prioritizing customer satisfaction.

GRINDING PROCCESS

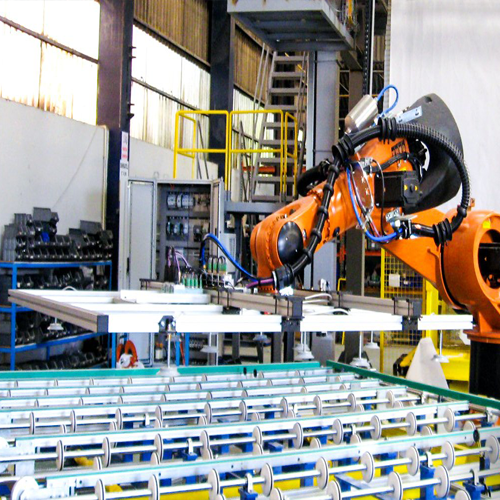

Grinding is an abrasive machining process that uses a grinding wheel or grinder as the cutting tool. Grinding is a subset of cutting, as grinding is a true metal-cutting process. Grinding is very common in mineral processing plants and the cement industry.

Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension. It has some roughing applications in which grinding removes high volumes of metal very rapidly.

GRINDING PROCCESS

Grinding is an abrasive machining process that uses a grinding wheel or grinder as the cutting tool. Grinding is a subset of cutting, as grinding is a true metal-cutting process. Grinding is very common in mineral processing plants and the cement industry.

Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension. It has some roughing applications in which grinding removes high volumes of metal very rapidly.

Corrosionpedia Explains Grinding

Grinding is a method of reducing the size of hard materials or sharpening tools, generally accomplished in several stages. To produce desired fineness of end products, grinding is done after crushing. For example, through crushing the mineral ore to below a certain size and finishing by grinding it into powder, the ultimate fineness depends on the fineness of dissemination of the desired mineral.

Grinding can be done wet or dry, depending on the process in use, but for dry grinding the materials first may need to be dried in cylindrical, rotary dryers.

Many machines are used for grinding, including:

- Hand-cranked knife-sharpening stones (grindstones)

- Handheld power tools such as angle grinders and die grinders

- Various industrial machines known as grinding machines

- Bench grinders often found in residential garages and basements

Grinding can produce very fine finishes and very accurate dimensions. It is usually better suited to the machining of very hard materials than is “regular” machining.

Property changes due to grinding include:

- Martensitic layer may form on the part, which leads to reduced material strength from microcracks

- Possible loss of magnetic properties on ferromagnetic materials

- Increased susceptibility to corrosion because of high surface stress

Grinding machines remove material from the work piece by abrasion, which can generate substantial amounts of heat. To cool the work piece so that it does not overheat and go outside its tolerance, grinding machines incorporate a coolant.

+90 (535) 543 76 74

+90 (535) 543 76 74

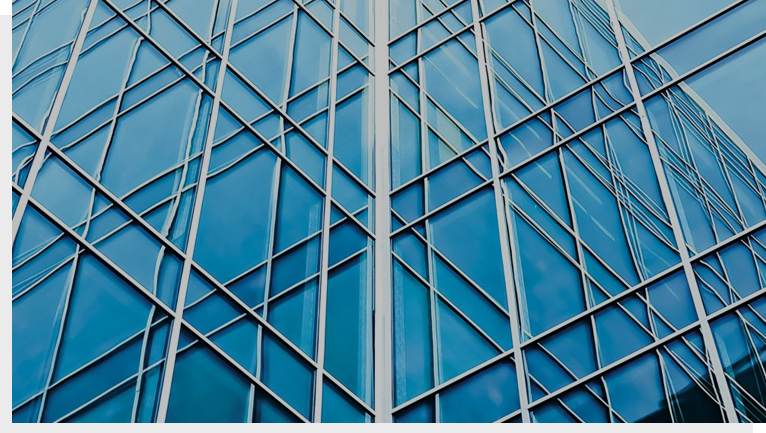

FLOAT GLASS

FLOAT GLASS TINTED GLASS

TINTED GLASS REFLECTIVE GLASS

REFLECTIVE GLASS LOW-E / SOLAR LOW-E GLAS

LOW-E / SOLAR LOW-E GLAS TEMPERED GLASS

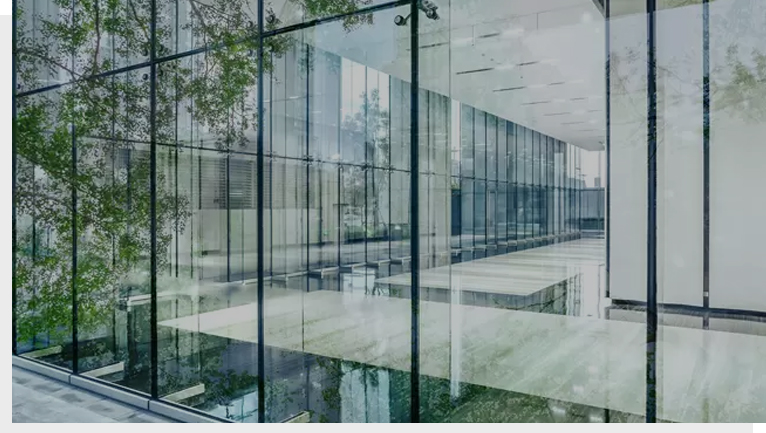

TEMPERED GLASS DECORATIVE GLASS

DECORATIVE GLASS LAMINATED GLASS

LAMINATED GLASS TRIPLE GLAZING SYSTEM

TRIPLE GLAZING SYSTEM DOUBLE GLAZING SYSTEM

DOUBLE GLAZING SYSTEM LAMINATION PROCESS

LAMINATION PROCESS AIRPORTS

AIRPORTS HOSPITALS

HOSPITALS UNIVERSITY & SCHOOL

UNIVERSITY & SCHOOL HOTELS

HOTELS SHOPPING MALL

SHOPPING MALL RESIDENTIAL BUILDING

RESIDENTIAL BUILDING RESIDENTAL & BUSINESS CENTER

RESIDENTAL & BUSINESS CENTER OTHERS

OTHERS +90 (262) 375 32 11

+90 (262) 375 32 11